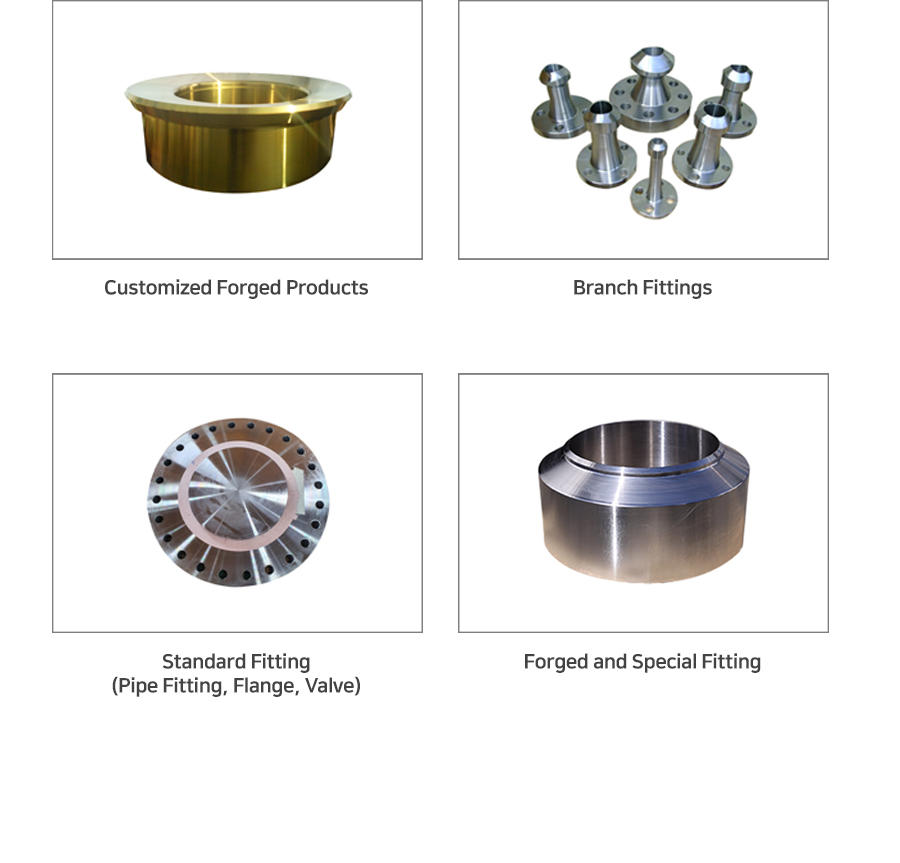

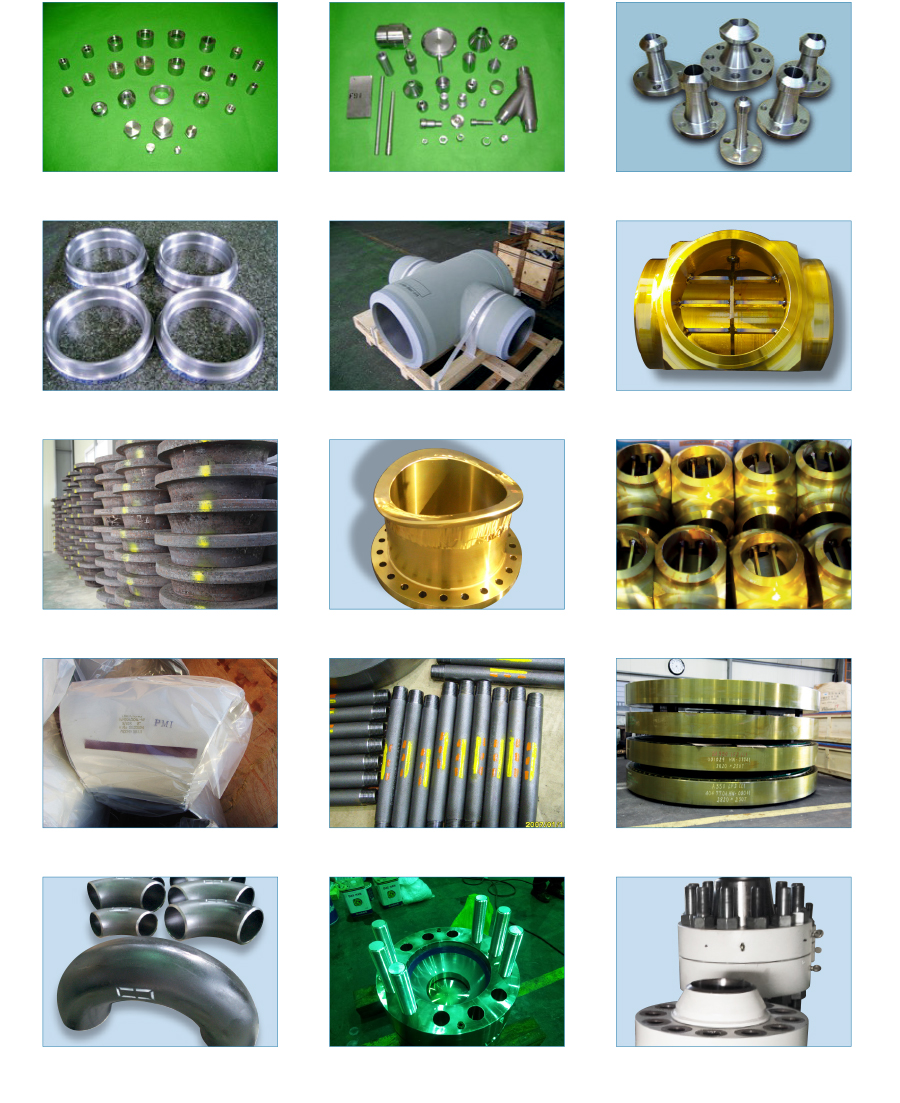

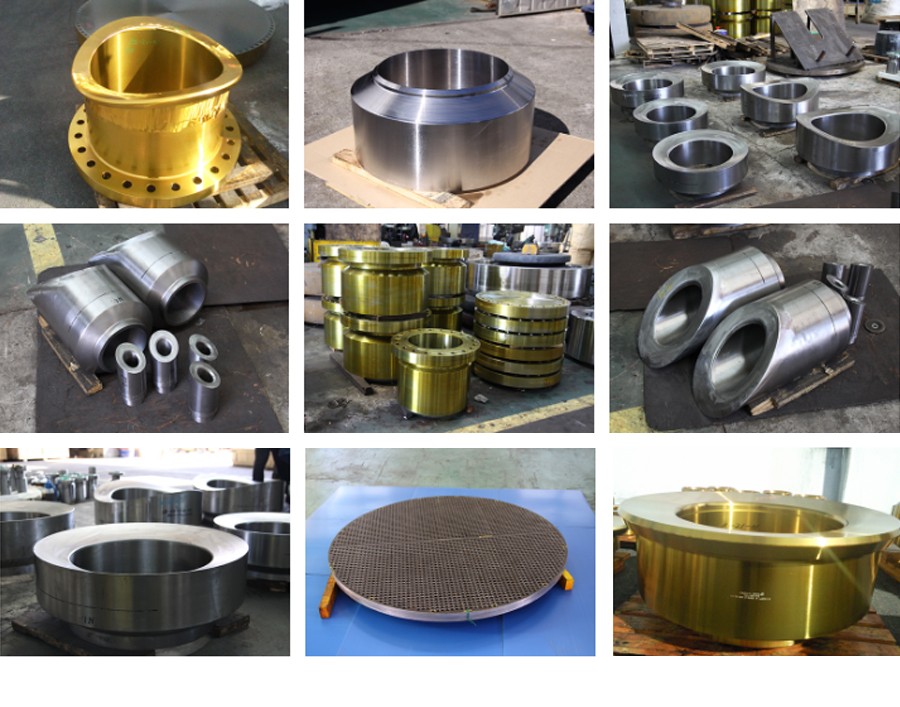

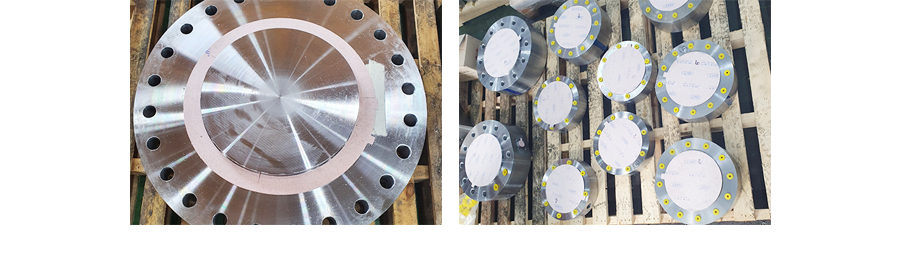

We, TF Tech, have been dedicated to quality improvement and process improvement for customer satisfaction since established. Our products are covered with standard and non-standard forged items.

Such as Customized Nozzle, Boss, Tube sheet and et cetera used in

fabrication for pressure vessel and heat exchanger

in the field of Oil & Gas and power plant industries.

We are keeping challenge to achieve customer satisfaction.

Please encourage us to continue to build for the future and keep

an eye on how we grow through continuous inquiry.

Sincerely yours TF TECH Co., LTD.

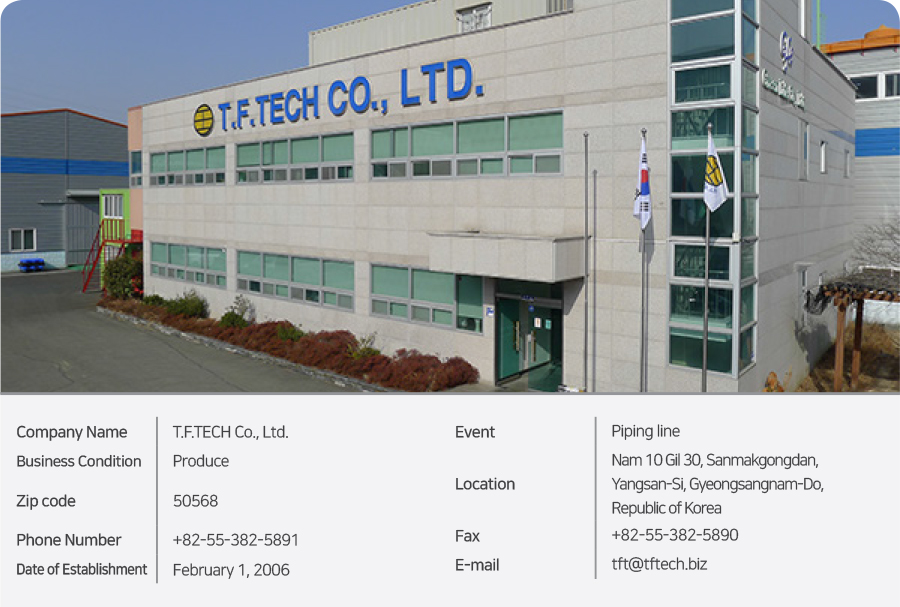

| Address | Nam 10 Gil 30, Sanmakgongdan, Yangsan-Si, Gyeongsangnam-Do, Korea |

|---|---|

| Tel | +82-51-583-8360 |

| Fax | +82-51-583-8362 |

| Address | Rm 503, 5F, Chang A Building, 434, Geumjeong-Gu, Busan, Korea |

|---|---|

| Tel | +82-51-583-8360 |

| Fax | +82-51-583-8362 |

| PROJECT NAME | PRODUCT | SITE | YEAR |

|---|---|---|---|

| EX-27 PROJECT | HEAD | THAILAND | 2017 |

| SUBAN CHILLER TRAIN 1-4 HEAT EXC | TUBE SHEET | MALAYSIA | 2017 |

| FLEXI HDPE PLANT FOR TAPID PROJECT | PIPE BUFFING | MALAYSIA | 2017 |

| PETRO CHEMICAL CORPORATION | U-TUBE | SINGAPORE | 2017 |

| CSR | FIN TUBE | SINGAPORE | 2017 |

| P27 FLEXI HDPE RAPID PROJECT (PV HE) | U-TUBE, TUBE | MALAYSIA | 2017 |

| CCW COOLER PLTU LONTOR | TUBE SHEET, HEAD | INDONESIA | 2017 |

| 160200 WESTMORELAND MODULE | PLATE | THAILAND | 2017 |

| NC2 Plant, Tube Bundle Replacement | U-TUBE | MALAYSIA | 2017 |

| 3080 PSR2 REVAMP PROJECT | FORGING ITEMS, TUBE | MALAYSIA | 2017 |

| Nimir Project | U-TUBE | MALAYSIA | 2017 |

| Qatar Gas Operating Ltd | TUBE SHEET, BAFFLE, FLANGE | UAE | 2017 |

| SPHERIPOL3305/SPHERIZONE3315 for RAPID | U-TUBE | MALAYSIA | 2017 |

| 1 UNIT TUBE BUNDLE FOR SUBAN CHILLER TRAIN 1-4 HEAT EXC | TUBE SHEET | INDONESIA | 2017 |

| PT.PERTAMINA | ELBOW | INDONESIA | 2016 |

| SPHERIPOL 3305 / SPHERIZONE 3315 for RAPID | TUBE & U-TUBE | MALAYSIA | 2016 |

| Covestro (Thailand) CO., Ltd. Crystallizer#6 Project | TUBE | THAILAND | 2016 |

| Rapid Project (AXFD001) | CUSTOMISED FLANGE | MALAYSIA | 2016 |

| CTCI CXN Improvement Project | TUBE, EXPENSION JOINT | MALAYSIA | 2016 |

| Rapid Project (AXFD001) Nihon Pall Ltd | U-TUBE | MALAYSIA | 2016 |

| Petronas Chemicals Olefins | TUBE SHEET, FLANGE, TUBE, EXPANTION JOINT | MALAYSIA | 2016 |

| CONOCO PHILIPS | DUPLEX(2205) BENDING TUBE | INDONESIA | 2016 |

| Petronas RAPID Project Package BXFD001 & 2 |

FLANGE | MALAYSIA | 2016 |

| PETRONAS LPG CHLORIDE TREATER | CUSTOMISED FLANGE, PIPE | MALAYSIA | 2016 |

| HPH BUKIT ASAM PROJECT BUKIT ASAM STEAM POWER PLANT |

OVERLAY TUBE SEET, U-TUBE, HEMI HEAD | INDONESIA | 2016 |

| BETARA COMPLEX DEVELOPMENT | CLADDING HEAD | INDONESIA | 2016 |

| CILACAP BLUESKY PROJECT | FLANGE, FITTING, SPECTACLE | INDONESIA | 2016 |

| HP HEATER LABUAN UNIT 1 & 2 (NO. E160N009) | FLANGE, NOZZLE | INDONESIA | 2016 |

| Rapid Pengerang (Sulphur Lock) | FLANGE | MALAYSIA | 2016 |

| Verasuwan_Vessel & Shell and Tube Heat Exchanger (16-8609) | U-TUBE | THAILAND | 2016 |

| BUKIT ASAM STEAM POWER PLANT PHASE II UNITS 3&4 (2X65 MW) |

MANWAY, NOZZLE | INDONESIA | 2016 |

| HP Heater Labuan unit 1&2 PT INDONESIA POWER / PLN |

INCONEL OVERLAY TUBE SHEET | INDONESIA | 2016 |

| PT Dabi Oleo | SHELL, HEAD | INDONESIA | 2016 |

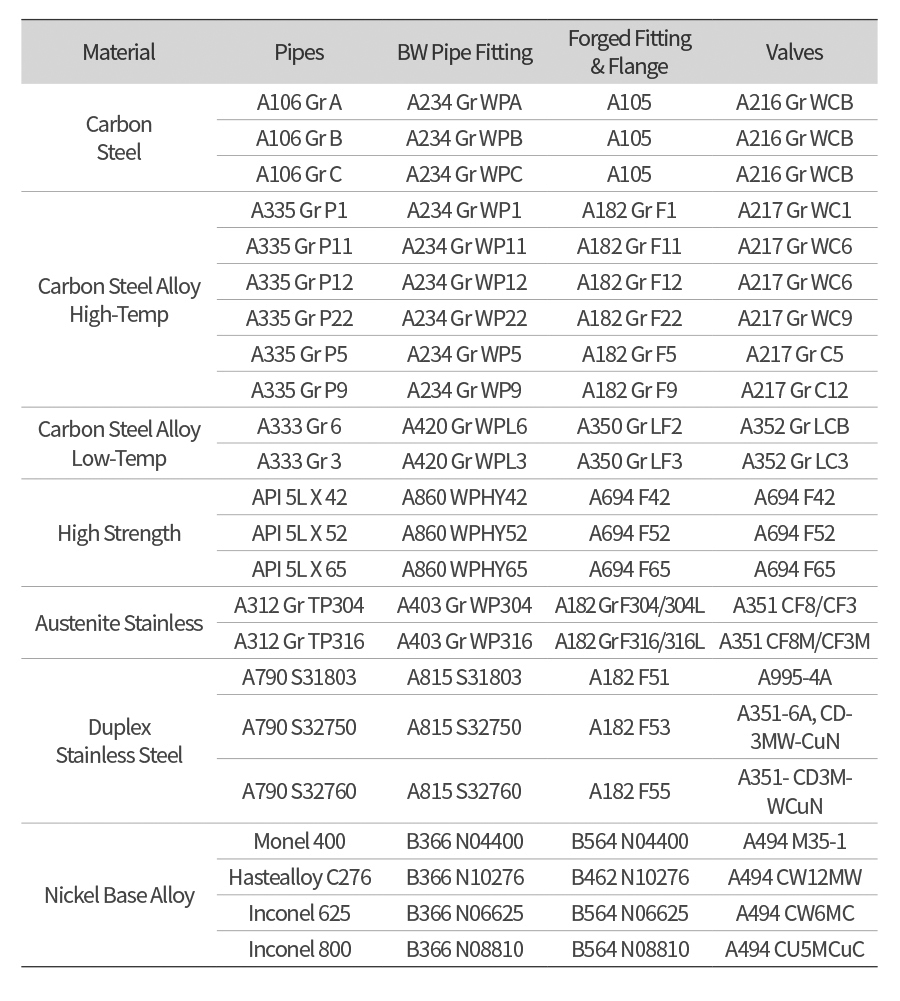

| Material | Material |

|---|---|

| Carbon Steel | A105 |

| A105 | |

| A105 | |

| Carbon Steel | A182 Gr F1 |

| A182 Gr F11 | |

| A182 Gr F12 | |

| A182 Gr F22 | |

| A182 Gr F5 | |

| A182 Gr F9 | |

| Carbon Steel Alloy Low-Temp | A350 Gr LF2 |

| A350 Gr LF3 | |

| High Strength | A694 F42 |

| A694 F52 | |

| A694 F65 | |

| Austenite Stainless | A182 Gr F304/304L |

| A182 Gr F316/316L | |

| Duplex Stainless Steel | A182 F51 |

| A182 F53 | |

| A182 F55 | |

| Nickel Base Alloy | B564 N04400 |

| B462 N10276 | |

| B564 N06625 | |

| B564 N08810 |

| Material | Material |

|---|---|

| Carbon Steel | A105 |

| A105 | |

| A105 | |

| Carbon Steel | A182 Gr F1 |

| A182 Gr F11 | |

| A182 Gr F12 | |

| A182 Gr F22 | |

| A182 Gr F5 | |

| A182 Gr F9 | |

| Carbon Steel Alloy Low-Temp | A350 Gr LF2 |

| A350 Gr LF3 | |

| High Strength | A694 F42 |

| A694 F52 | |

| A694 F65 | |

| Austenite Stainless | A182 Gr F304/304L |

| A182 Gr F316/316L | |

| Duplex Stainless Steel | A182 F51 |

| A182 F53 | |

| A182 F55 | |

| Nickel Base Alloy | B564 N04400 |

| B462 N10276 | |

| B564 N06625 | |

| B564 N08810 |

| Material | Material |

|---|---|

| Carbon Steel | A105 |

| A105 | |

| A105 | |

| Carbon Steel | A182 Gr F1 |

| A182 Gr F11 | |

| A182 Gr F12 | |

| A182 Gr F22 | |

| A182 Gr F5 | |

| A182 Gr F9 | |

| Carbon Steel Alloy Low-Temp | A350 Gr LF2 |

| A350 Gr LF3 | |

| High Strength | A694 F42 |

| A694 F52 | |

| A694 F65 | |

| Austenite Stainless | A182 Gr F304/304L |

| A182 Gr F316/316L | |

| Duplex Stainless Steel | A182 F51 |

| A182 F53 | |

| A182 F55 | |

| Nickel Base Alloy | B564 N04400 |

| B462 N10276 | |

| B564 N06625 | |

| B564 N08810 |

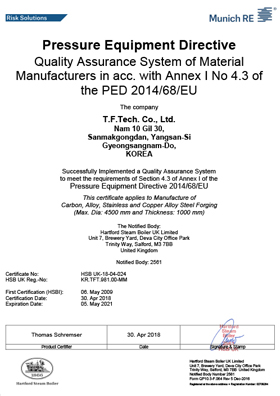

ISO 9001 Certificate (2018)

ISO14001 Certificate

PED

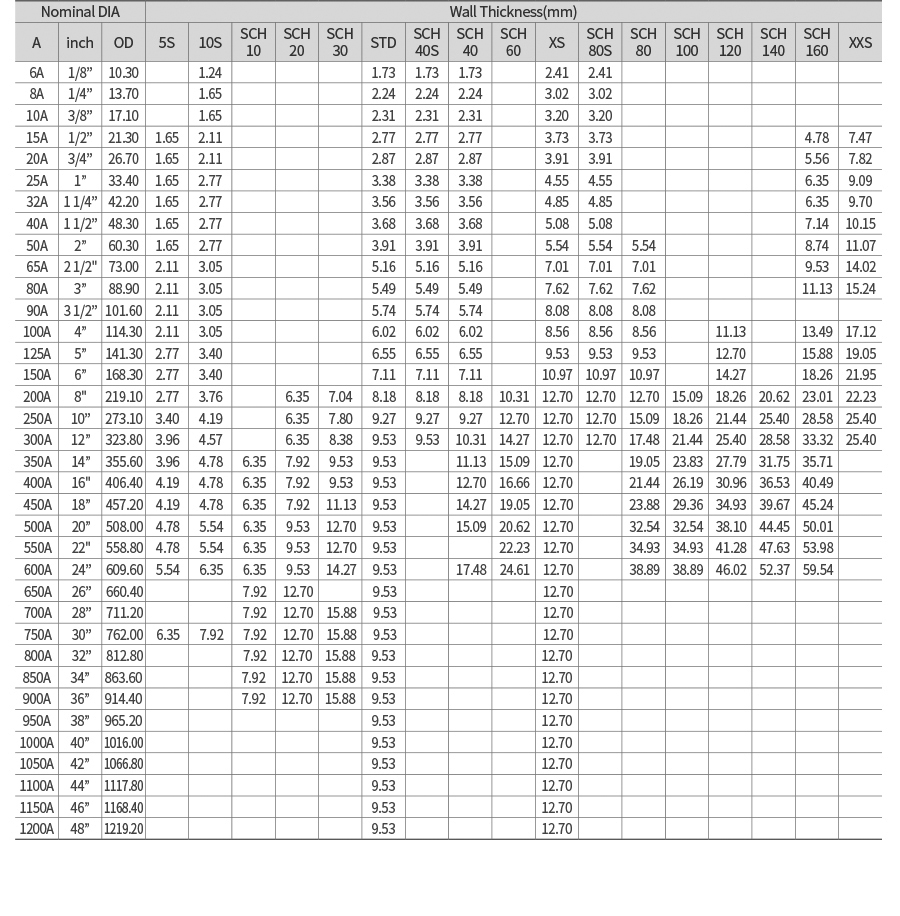

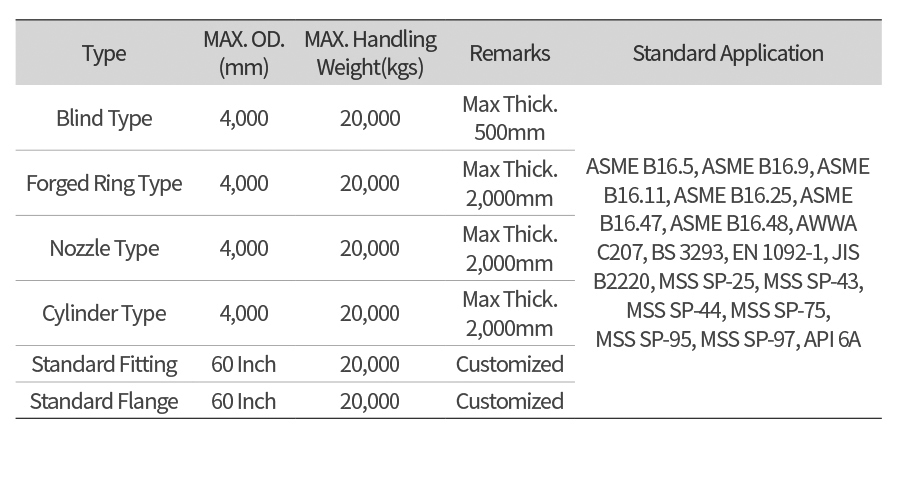

| Type | MAX. OD.(mm) | MAX. Handling Weight(kgs) |

Remarks | Standard Application |

|---|---|---|---|---|

| Blind Type | 4,000 | 20,000 | Max Thick. 500mm |

ASME B16.5, ASME B16.9, ASME B16.11, ASME B16.25, ASME B16.47, ASME B16.48, AWWA C207, BS 3293, EN 1092-1, JIS B2220, MSS SP-25, MSS SP-43, MSS SP-44, MSS SP-75, MSS SP-95, MSS SP-97, API 6A |

| Forged Ring Type | 4,000 | 20,000 | Max Thick. 2,000mm | |

| Nozzle Type | 4,000 | 20,000 | Max Thick. 2,000mm | |

| Cylinder Type | 4,000 | 20,000 | Max Thick. 2,000mm | |

| Standard Fitting | 60 Inch | 20,000 | Customized | |

| Standard Flange | 60 Inch | 20,000 | Customized |

| Equipment | Description | Maker | Q’ty |

|---|---|---|---|

| Turning Machine | ø3,000 * 2,000 | Japan | 1 |

| Turning Machine | ø1,800 * 2,000 | Japan | 1 |

| Turning Machine | ø1,200 * 1,600 | Japan | 1 |

| NC Turning Machine | ø1,800 * 2,000 | Japan | 1 |

| Band Sawing Machine | ø450 * 430 | Korea | 1 |

| Lathe | ø900 * 3,000L | Korea | 1 |

| Lathe | ø580 * 1,000L | Korea | 1 |

| Lathe | ø400 * 1,060L | Korea | 1 |

| Lathe | ø720 * 3000L | Korea | 1 |

| Horizontal Lathe | ø630 * 1,000L | Korea | 1 |

| Radial | ø2000 | Korea | 1 |

| Radial | ø2000 | Japan | 1 |

| Vertical Drill | ø560 | Korea | 1 |

| Portable Drill | ø21 | Korea | 1 |

| Portable Drill | ø13 | Korea | 1 |

| Plano Miller | X3000-Y1650-Z1300 | Korea | 1 |

| PLASMA | 8.7KW | Korea | 1 |

| Welder | 12KW | Korea | 1 |

| Welder | 10KW | Korea | 1 |

| Welder | 200A | Korea | 1 |

| Compressor | 5HP | Korea | 1 |

| Hoist Crane | 10Ton | Korea | 1 |

| Hoist Crane | 5Ton | Korea | 2 |

| Marking Machine | MCU-100N | Korea | 1 |

| Marking Machine | Own Customize | Korea | 1 |

| Lapping Machine | Own Customize | Korea | 1 |

Head Office : Nam 10 Gil 30, Sanmakgongdan, Yangsan-Si, Gyeongsangnam-Do, Korea

T.F.Tech : Rm 503, 5F, Chang A Building, 434, Geumjeong-Gu, Busan, Korea

Tel : +82-51-583-8360 / Fax : +82-51-583-8362 / E-mail : tft1@tftco.co.kr / tft2@tftco.co.kr

Copyright ⓒ 2021 T.F.Tech ALL RIGHTS RESERVED.